Kashifuji-isms

Kashifuji has been producing hobbing machines for more than 100 years.

Review our culture and commitments in which has produced a very reliable hobbing machine.

-

The DNA of

Kashifuji 01

01The DNA of Kashifuji

Historical accounts show, Kamitoba Kamonden, Kyoto City, (where we are engaged in manufacturing), was home to Jomon-style ruins (from about 14,000 to 300 BC), and this area was also where the ancient people had been manufacturing various items for about 10,000 years. A number of elaborate earthenware and stone scrapers were discovered here. We (Kashifuji), who are engaged in "MONOZUKURI (Manufacturing)" in this place, continue to create products that contribute to today’s society, while thinking back to the spirit of manufacturing at that time.

-

Gear

Develop

-ment 02

02Gear Development

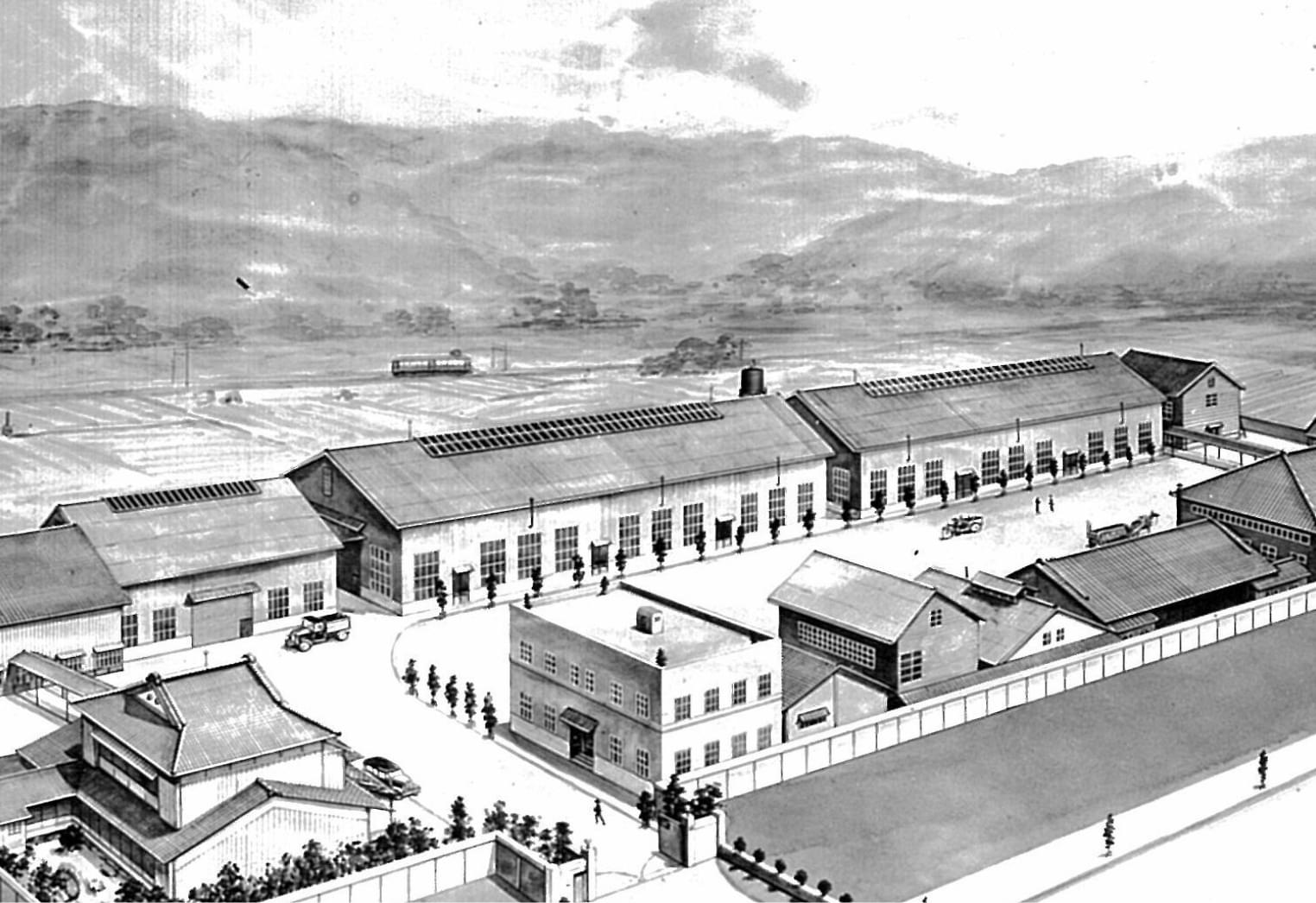

In 1913, our founder, Mr. Tomesaburo Kashifuji, was engaged in manufacturing machinery related to Nishijin textiles and textile dyeing machines produced in Kyoto. Around this same time, Japan's first streetcars, a state-of-the-art urban transportation system, was operating in Kyoto, and he began working on the production of hobbing machines with interest in the gears used in the street cars and to improve the performance of the gears used in dyeing machines.

-

The Growth of Kashifuji

03

The Growth of

KashifujiSince its’ founding, more than 110 years ago, Kashifuji has developed and launched a variety of products for the Gear Industry. Kashifuji developed Japan’s 1st Hobbing Machine in 1918.

-

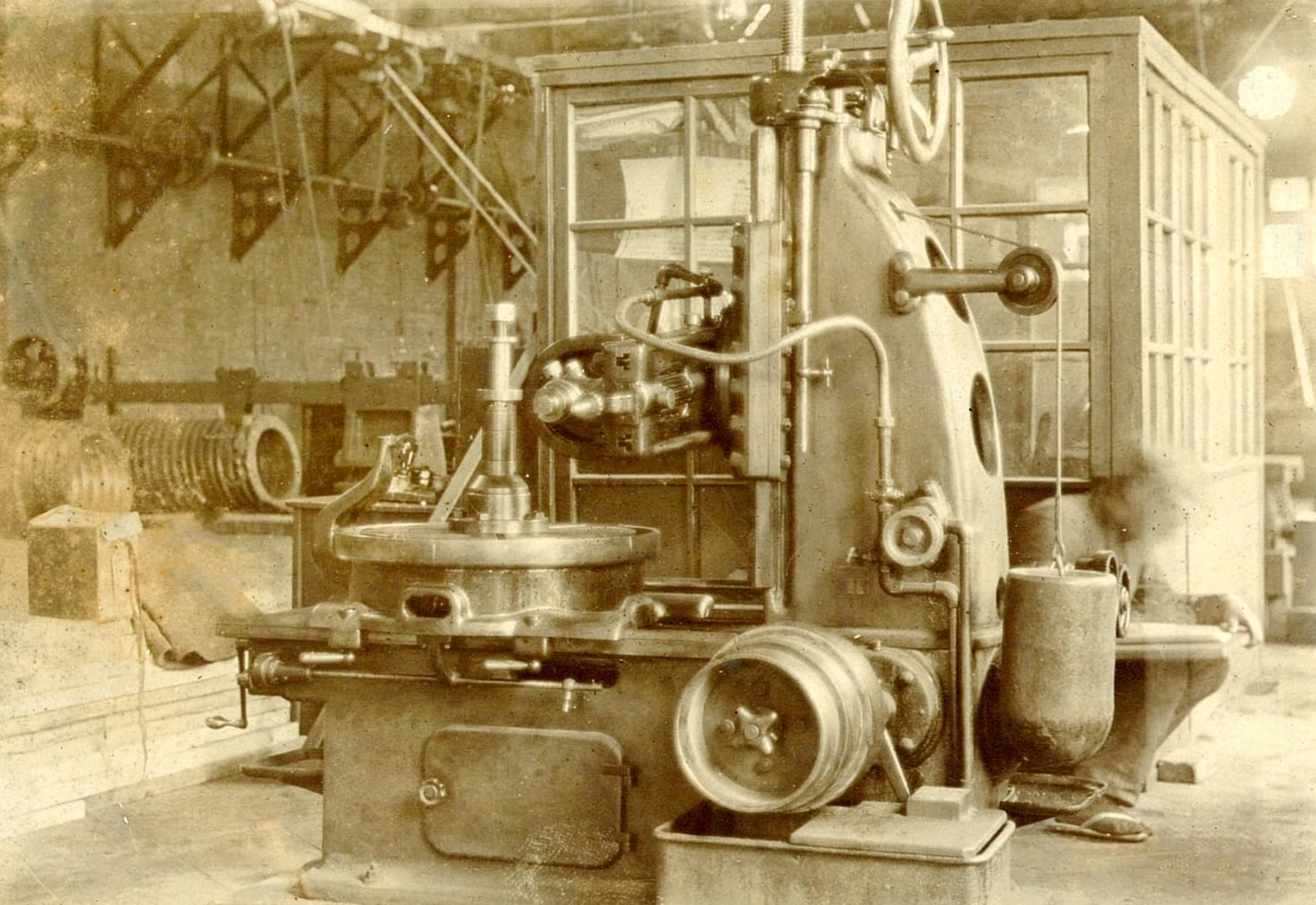

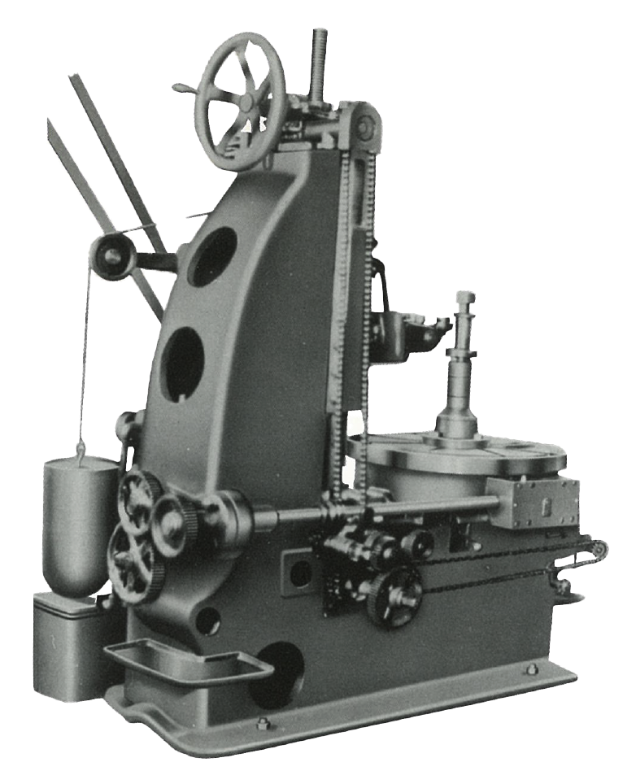

1918

191840-inch

Hobbing

Machine

We developed Japan's First Trial Hobbing Machine. As an in-house facility, we manufactured and sold replacement gears for the Japan’s first municipal electric railways (Kyoto City Trams). Soon after, we began manufacturing and selling hobbing machines.

-

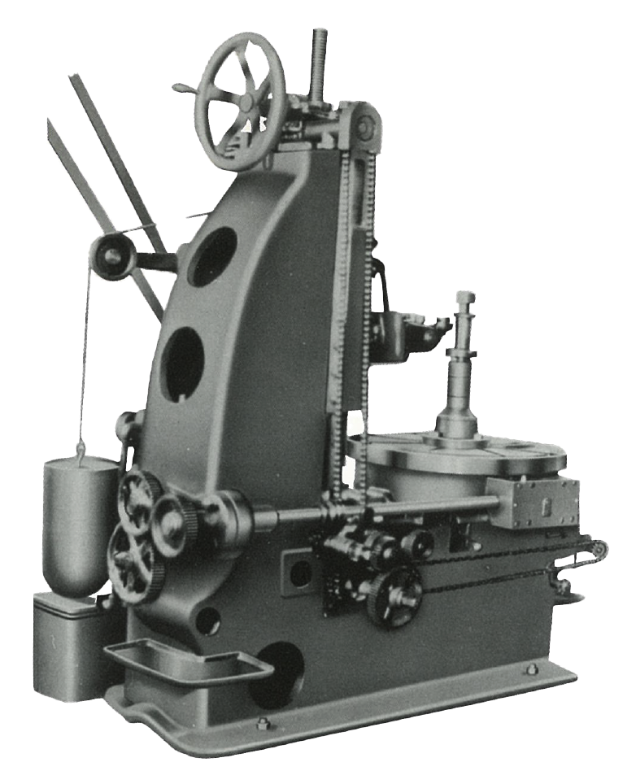

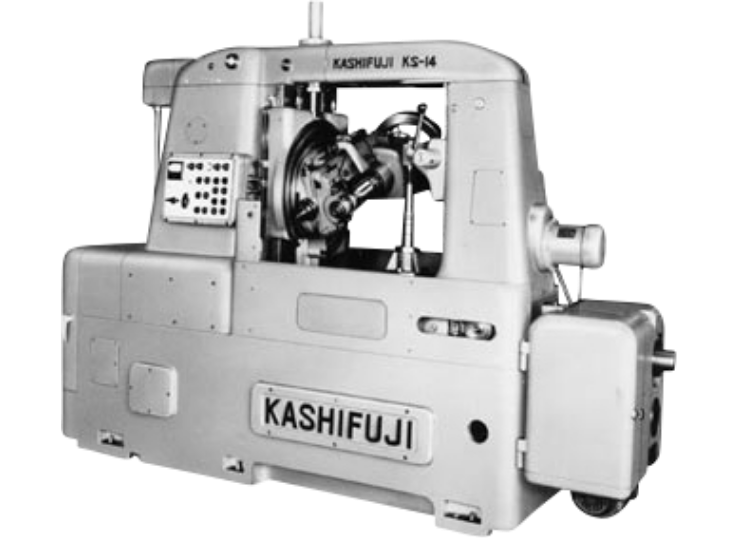

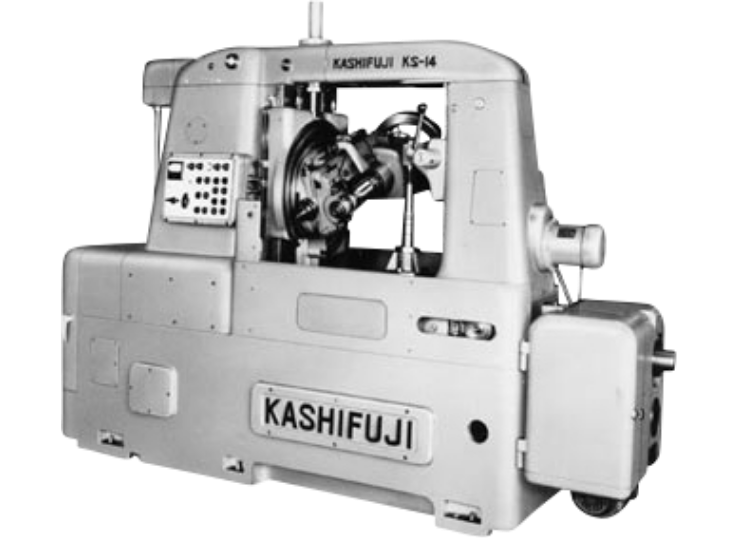

1956

1956KS14 type

High Production

Hobbing Machine

We developed a Hobbing Machine that contributed to Japan's Rapid Economic Growth Period. The automatic cutting cycle system was adopted for the first time, and the gear cutting time was dramatically shortened compared with the conventional cutting time. The machine made a significant contribution to the efficient manufacture of transmission gears for passenger cars of various automobile makers.

-

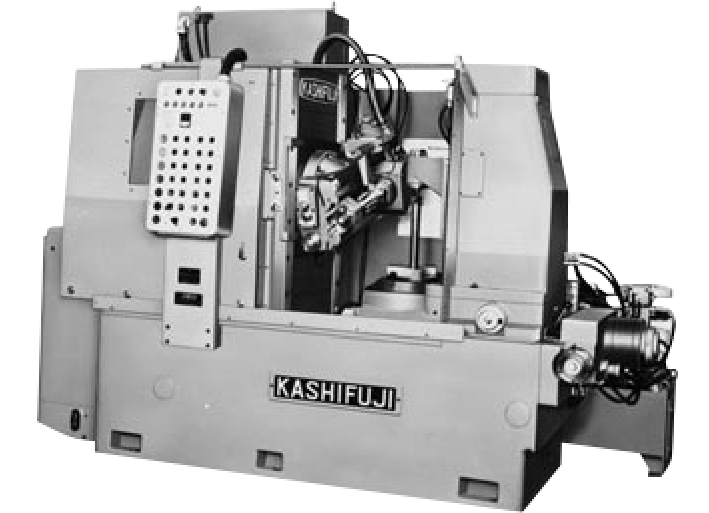

1982

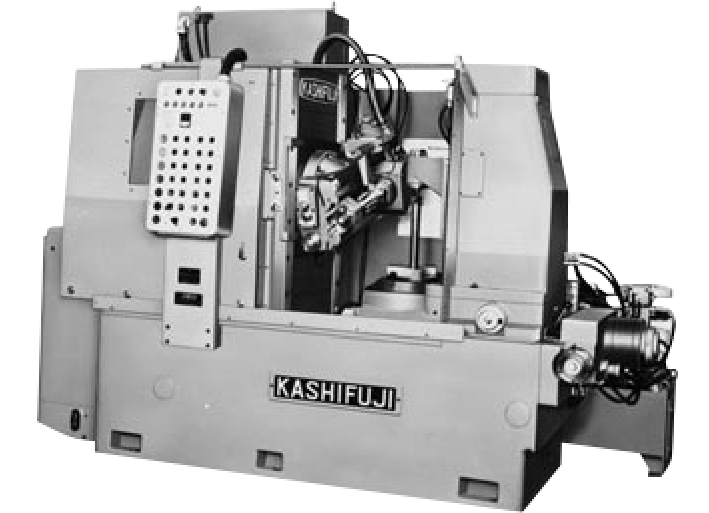

1982KS300NC type

Hobbing Machine

We developed Japan’s First All Axes NC Hobbing Machine. The selection & setting of change gears for hob rotation, indexing, differential and axial feed and hob head was no longer required. The change-over time of jig fixtures, hob cutter and cutting conditions which previously required about an hour was reduced to just a few minutes by simple part program entries.

-

2012

2012KPS20 type

Gear Skiving Machine

We developed Japan’s first Gear Skiving Machine. The Gear Skiving Machine is characterized by the capability to process internal gears. The cutting is performed by the rotational motion of a tool rather than tool reciprocating motion such as gear shaping process. Therefore, the machining time can be shortened compared with the gear shaper, and at the same time, the lead shape can be modified. In addition, the tools used for the Gear Skiving Machine can be manufactured at a very low cost compared to the tools used for a broaching machine.

-

-

Philosophy Kashifuji's philosophy04

Manufacturing of User-Friendly Machinery

The “Friendliness” we think is to create the best machines from the operator’s point of view. In other words, a machine that delivers high-precision, high-quality, many years of reliable service with less down time, and is easy to use. That is the philosophy that we have pursued since our founding. High-quality machine tools must be able to be used for a long period of time once they are installed, as well as maintaining precision and functionality. The value of a machine tool lies in its’ productivity and durability. We believe it is most important to have our machine tools stay in continuous production without downtime.

-

01

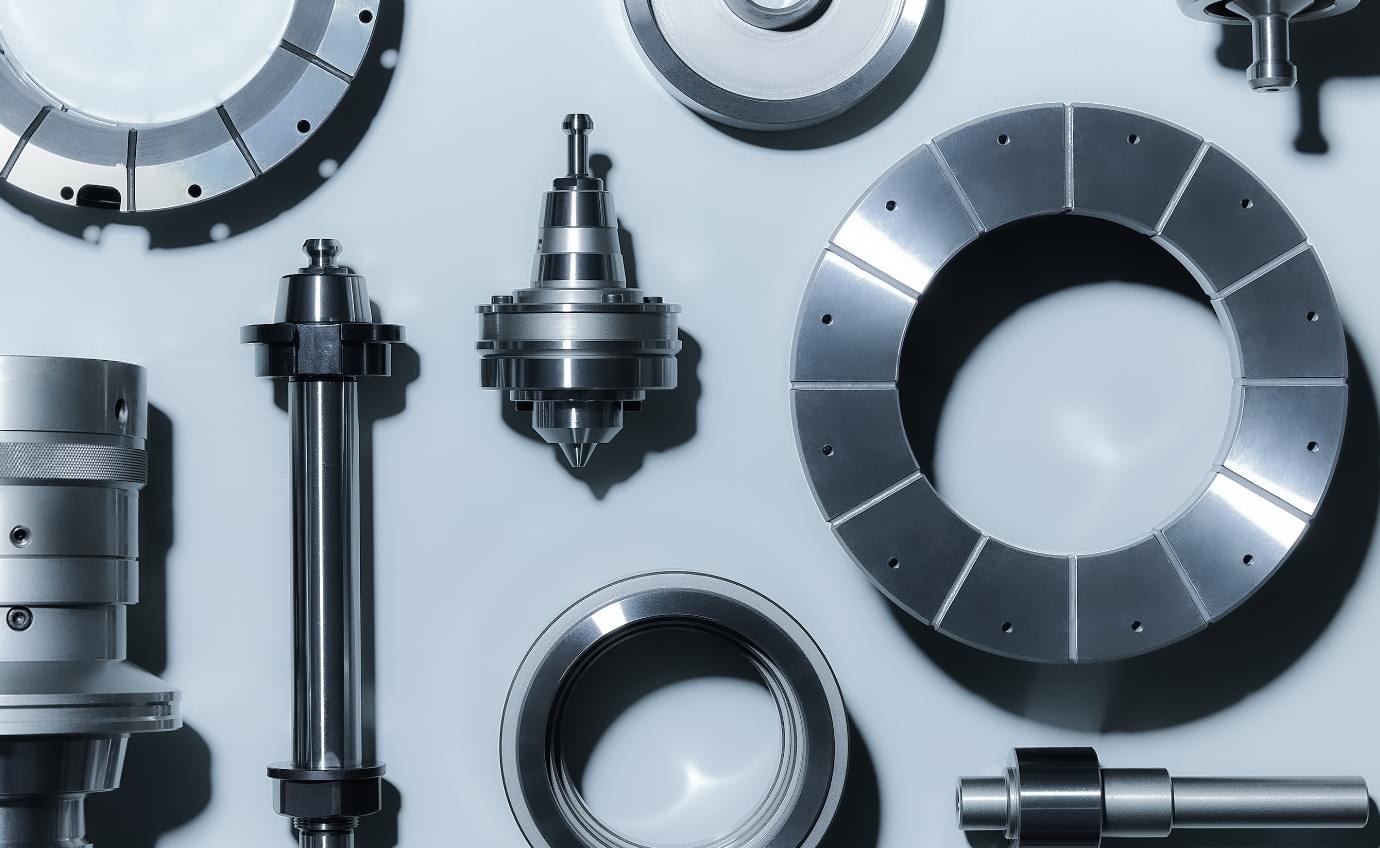

01High-Quality Manufacturing

We have built hobbing machines for over 100 years. Based on this extensive experience of manufacturing hobbing machines, we are still continuing to make improvements to the machine even now, with the goal of building the world’s best hobbing machines. In order to produce the world’s best hobbing machines, almost all of the final finishing processes for the machine core components are in-house manufactured, and the quality of these parts and assemblies for the machine is tightly controlled. Moreover, we are focused on hand scraping of machine ways, which require high precision and durability. The precise manufacturing method of the master worm gear set produces the extremely high hobbing accuracy.

-

02

02Detailed Customized Design

We excel at building machines to meet the specifications demanded by our customers due to the high degree of completeness of our products. With the goal to produce a machine that is both friendly to users and easy to use, we continue to refine our ability to make proposals that meet customers’ preferences. By delivering customized machines to each customer, we have been improving our design capabilities and developing capabilities that consistently lead the gear industry.

-

03

03Support System

Older machines can be kept in service as we put effort into machine maintenance and supplying spare parts. A follow-up system is fully established until the machines are retired (After-sales service may not be available on some of the parts and repair requirements.) In addition, we provide our customers with guidance on how to properly use our machines and we hold seminars to educate them on gear processing and manufacturing. We have formed alliances with local partner companies for our overseas customers, and have established a double support system consisting of our educated local staff and our service staff.

-

04

04Developing Human Resources

"Developing Human Resources" is the Kashifuji's preferential commitment. The machines that we produce at the request of our customers are not uniform. The ability to carefully create products with different specifications one by one is solely due to the ability of Kashifuji’s people. These individual skills have been cultivated through many years of experience and achievements, and the people who inherit their predecessor's skills and spirit accumulate more experience. This technology transfer “relay” creates the people of Kashifuji! We aim for the next 100 years by passing on the baton of technology to the younger generation.